SICK products & Parts Saudi Arabia - [email protected] - 00966-13-8584606 - 00966-531451541

|

Registration sensors

The variety of tasks in automated production processes today, such as in packaging and printing machines, require sensors with the highest performance standards. Typical applications are the detection of visible and non-visible marks, labels and colors at high speeds as well as the detection of small parts and precise positioning. SICK offers a wide range of contrast, markless, color, luminescence, fork and array sensors to solve this wide spectrum of demanding tasks. |

|

Contrast sensors

Contrast sensors are primarily used in packaging/printing machines for the detection of printed or control marks. SICK's line of KT contrast sensors detects even the smallest contrasts at the ... |

Color sensors

Color sensors detect the color of a surface. The sensors cast light (red, green, and blue LEDs) on the objects to be tested, calculate the chromaticity coordinates from the reflected radiation ... |

|

Luminescence sensors

Luminescence sensors detect visible and non-visible marks that illuminate when using ultraviolet (UV) light. Fluorescent material and marks are reliably detected independently of their pattern, ... |

Glare sensors

The Glare sensor detects and distinguishes glare on even surfaces. It also provides maximum reliability and saves costs. Previously, gloss on object surfaces was a disruptive factor that ... |

|

Fork sensors

SICK fork sensors combine senders and receivers in a single housing, meaning that they can be adjusted quickly. Thanks to the precise, focused light beam and the high detection accuracy, the ... |

Register sensors

The register sensor line complements our wide range of contrast sensors. As specialists in the register control of printing presses they offer an optimal solution to detect marks in tough print ... |

|

Array sensors

Array sensors operate on the proximity scanning principle. They detect even the smallest edges based on differences in grayscale values within the field-of-view. Positioning of, for example, a ... |

Pattern sensors

The pattern sensor is a proximity-scanning opto-electronic sensor. Distinctive patterns in an image are used as a reference for the subsequent, accurate detection and positioning of objects. A ... |

|

Photoelectric sensors

SICK's vast range of photoelectric sensors offer precise optics and advanced technology, creating market-leading solutions with sensor intelligence. By using the latest SIRIC® and LED technologies, these sensors offer the highest level of operational reliability regardless of any interference factors. Additional sensor information can be used to simplify modern production processes. This extensive range of photoelectric sensors is used in many automation applications around the world. |

|

Automation light grids

Two-dimensional inspection or counting tasks are important in automation. SICK’s automation light grids can be used in a number of these solutions, such as detecting and counting irregularly shaped objects, people and vehicles, and checking for presence and pallet overhang detection. The tasks are so versatile that one light grid cannot fulfill the requirements of every application. Light grids from SICK offer multiple ranges, heights, sizes, orientations, and resolutions which simplify integration through high flexibility and performance. |

|

Capacitative and magnetic proximity sensorsProximity sensors provide non-contact detection of a wide variety of objects and media. SICK’s sensors are perfectly suited to industrial applications and requirements. SICK’s capacitive and magnetic proximity sensors offer a long service life, extreme ruggedness and the utmost precision. SICK intelligently and reliably solves industry-specific and individual automation tasks.

|

|

Detection and ranging solutions

The LiDAR (Light Detection and Ranging) laser measurement technology offers solutions for a wide range of applications. The two- or more-dimension contour data recorded can be processed both internally and externally. The technology is ideal for indoor and outdoor applications, for example anti-collision in ports, classification in traffic, detection in building automation, or position evaluation in navigation, for example. |

|

Distance sensors

SICK has a wide range of optic and ultrasonic solutions that measure from sub-microns to kilometers. They solve measuring, detecting and positioning applications using triangulation and time-of-flight modes. Sensors using triangulation are ideal for short-range, highly precise measurement. They can inspect miniature parts, thickness and shape, etc. Time-of-flight sensors work at longer distances, are not influenced by reflectivity or ambient light − perfect for positioning AS/RS, rail cars and gantry cranes. |

|

Dust Measuring Devices

SICK is setting new standards in dust measurement with its rugged and low-maintenance measuring devices for detecting and monitoring dust concentrations. All dust measuring devices are easy to integrate into existing applications – and offer straightforward installation and commissioning along with user-friendly operation. |

|

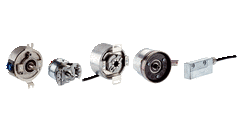

Encoders

Paths, position, angle – an encoder is the ideal solution when it comes to precise position detection in industrial automation. The same applies to measuring revolutions and rpm as well as speed and acceleration. High-resolution optical encoders and extremely rugged magnetic encoders complement one another perfectly and permit exact measurements in all kinds of applications. Rotary encoders are available as incremental and absolute encoders. Wire draw encoders and linear encoders with a measuring element are available in linear measuring technology. |

|

Fiber-optic sensors and fibers

When installation space is extremely limited or the objects to be detected are tiny, fiber-optic sensors are the ideal solution. If it is necessary for even higher requirements to be fulfilled, such as sensing range, temperature resistance, material durability or a flexible mounting process, the intelligent combination of sensors and fiber-optic cables can provide the perfect solution. A wide range of fiber-optic cables with application-specific optical heads ensure that every need is met. |

|

Flow measurement technology

Flow measurement technology is used in nearly all industries. SICK has the tools to meet this many-faceted challenge and offers a comprehensive product portfolio of innovative sensor technology. Whether as custody transfer meters or measuring devices for monitoring and control: Flow measurement technology from SICK always works safely and reliably on the basis of the most up-to-date technology - even under difficult process and ambient conditions. |

|

Fluid sensors

Optimized control of process parameters is the main driver for increasing efficiency and reducing input of valuable resources. Whether it's pressure measurement, temperature measurement, level control or flow metering – SICK offers a wide range of solutions for measuring process variables for liquids, gases and bulk solids and protecting against overfill and dry run. SICK devices are rugged and easy to use. Innovative sensor technology enables accurate, universal measurement independent of material type. |

|

Identification solutions

Product traceability and anti-counterfeiting solutions require reliable automatic identification products. SICK offers the three most common industrial identification technologies: laser-based scanners for 1D codes, image-based 1D and 2D code readers, and RFID readers. Integrated interfaces enable the readers to communicate inside industrial networks and innovative functionality makes commissioning and operation easy. |

|

Inductive proximity sensors

Millions of inductive proximity sensors are currently in use in virtually all industries. They detect metal objects without contact, and are characterized by a long service life and extreme ruggedness. With the latest ASIC technology, SICK's sensors offer the ultimate in precision and reliability. SICK can provide the right solution to meet your requirements every time – from cylindrical or rectangular standard sensors with single, double or triple operating distance, to special sensors for explosive zones and harsh environments. Our sensors are the intelligent, reliable route to implementing industry-specific and customized solutions to any task involving automation. |

|

Inertial sensors

Knowing the position of objects is essential for process automation in mobile applications in particular. SICK offers a wide range of inertial sensors for this purpose. The product portfolio ranges from conventional static through dynamic inclination sensors which deliver accurate position information at all times, even in accelerated applications. |

|

Integration products

Integration products from SICK enable easy connection and networking of a wide variety of sensors at the field level as well as transmission of sensor data into the cloud. In keeping with Industry 4.0, the data is provided directly or in preprocessed form in order to operate higher-level processes such as predictive maintenance, track and trace and quality control. |

|

Localization solutions

Logistic processes in the field of warehousing and production are subjected to a continuous pursuit of greater efficiency. This can be increased significantly with the tracking of objects, localization of AGV system fleets or Asset Analytics.SICK offers comprehensive indoor localization solutions for the monitoring, control and data evaluation of freely-moving assets and autonomous platforms. |

|

Machine vision

Vision solutions are ideal for automated inspection and measurement tasks. SICK’s 2D and 3D vision cameras can be used to solve a wide range of applications where there is a need to measure, locate, inspect and identify. Our vision products are built for industrial environments, carefully designed to leverage SICK's 60-plus years of experience with industrial sensors. |

|

Magnetic cylinder sensors

Innovative cylinder sensors from SICK. Features like ease of handling, the option of an analog output, optimum switching characteristics, suitability for use in the food and beverage industry, support for the latest IO-Link technology, and universal mounting options with our comprehensive range of adapters, magnetic cylinder sensors from SICK are equipped for all installation locations and conditions. |

|

Motor feedback systems

Commutation, position and speed measurement with the corresponding number of interfaces used to require three sensors. Today, SICK motor feedback systems offer these functions in a single device. A consistent mechanical interface allows for a high level of flexibility. SICK motor feedback systems are also setting standards for electrical interfaces such as HIPERFACE® and HIPERFACE DSL®. They meet important requirements including temperature resistance, high resolution, and multiturn design. Certification to SIL2 permits implementation of the Machinery Directive as per EN ISO 13849. |

|

Opto-electronic protective devices

pto-electronic protective devices are the first choice in order to implement maximum productivity for machines and plants. Unlike fences and doors, they do not limit during handling or material transport and provide a better view in the machine room. The broad portfolio comprehensively meets the requirements of hazardous point protection, access protection, and hazardous area protection. Coordinated complete systems can be built using a SICK-specific interface. |

|

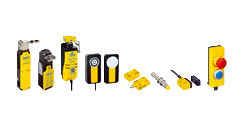

Safety switches

Safety switches are indispensable in any application where safety is required for people and machinery. They are used for protecting movable physical guards, determining the position of dangerous movements, and the safe stop function. The portfolio is divided into electro-mechanical and non-contact safety switches, safety locking devices, and safety command devices. In conjunction with safe control solutions, SICK offers ideal complete solutions from a single source. |

|

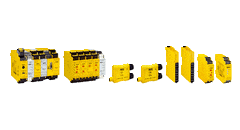

sens:Control - safe control solutions

As well as focusing on increasing productivity, intelligent machine design also delivers optimum quality and safety. sens:Control – safe control solutions by SICK meet these requirements. The product portfolio includes safe series connection, safety controllers and safety relays. The products impress with easy commissioning, modularity, and optimum integration into automation processes – for optimum interaction between human and machine. |

|

Traffic sensorsAdded safety – fewer backups: These are the key requirements of traffic service providers. Intelligent traffic sensors are absolutely fundamental to ensuring state-of-the-art traffic guidance technology. With its sophisticated equipment for measuring visual range, visibility, and wind speed, as well as detecting overheight, SICK is helping to find solutions to these tasks.

|